Aluminum pergola parts offer a perfect blend of aesthetics and functionality, elevating your outdoor space into an oasis of comfort and style. These versatile components are meticulously engineered to provide structural integrity, weather resistance, and a touch of elegance to your pergola.

From beams and rafters to posts, brackets, and connectors, the wide range of aluminum pergola parts empowers you to customize your pergola to match your unique vision and architectural style. Dive into the world of aluminum pergola parts and discover the endless possibilities for transforming your outdoor living area.

Types of Aluminum Pergola Parts

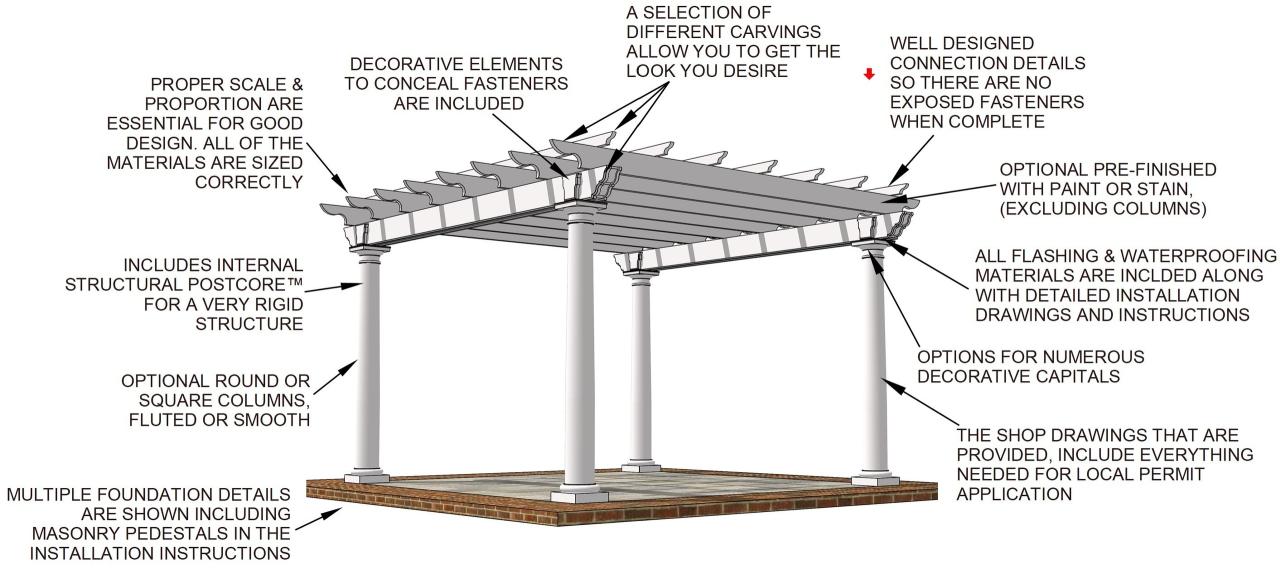

Aluminum pergolas offer a durable and stylish outdoor living solution, with various parts available to customize their design and functionality. These parts can be categorized based on their purpose and function, including beams, rafters, posts, brackets, and connectors.

Aluminum pergola parts offer durability and low maintenance, making them a popular choice for outdoor structures. However, for those seeking a more natural aesthetic, wooden pergolas with retractable roofs provide an elegant and functional solution. These pergolas combine the beauty of natural wood with the convenience of a retractable roof, allowing you to enjoy the outdoors while protecting yourself from the elements.

Aluminum pergola parts can be seamlessly integrated into these wooden structures, providing additional support and stability.

Beams, Aluminum pergola parts

Beams are the primary horizontal supports that run along the length of the pergola. They provide structural integrity and support the rafters. Beams come in different sizes and thicknesses, depending on the size and weight of the pergola. Common beam profiles include square, rectangular, and I-beam.

Rafters

Rafters are the secondary horizontal supports that run perpendicular to the beams. They provide additional support and create the framework for the roof. Rafters can be spaced evenly or at varying intervals, depending on the desired roof pitch and load capacity.

Aluminum pergola parts offer durability and low maintenance, making them a popular choice for outdoor structures. Pergolas, with their elegant columns and open-air design, provide shade and privacy while enhancing the aesthetics of any outdoor space. Whether you’re looking to create a cozy seating area or an outdoor dining room, aluminum pergola parts provide a versatile and long-lasting solution.

Posts

Posts are the vertical supports that anchor the pergola to the ground. They are typically made of thicker aluminum than beams and rafters and can be embedded in concrete footings for stability. Posts come in different heights and styles, including round, square, and decorative.

Brackets

Brackets are used to connect beams, rafters, and posts together. They provide additional support and ensure the structural integrity of the pergola. Brackets can be simple angle brackets or more complex connectors with multiple attachment points.

Connectors

Connectors are specialized hardware used to join aluminum pergola parts. They include bolts, nuts, washers, and other fasteners. Connectors ensure the secure and durable assembly of the pergola.

Materials and Finishes

The selection of aluminum alloys and finishes for pergola parts is crucial to ensure durability, aesthetics, and longevity. Aluminum alloys offer varying properties, while finishes provide protection and enhance the visual appeal of the pergola.

Aluminum Alloys

Common aluminum alloys used in pergola parts include:

- 6061-T6: A strong and versatile alloy with excellent corrosion resistance, making it suitable for coastal areas.

- 6063-T5: A more economical alloy with good strength and durability, suitable for general-purpose applications.

- 7075-T6: A high-strength alloy used for demanding applications where maximum strength is required.

Finishes

Aluminum pergola parts can be finished with various methods to enhance their durability and aesthetics:

- Powder Coating: A durable finish applied electrostatically and baked to form a hard, protective layer. It offers a wide range of colors and textures.

- Anodizing: An electrochemical process that creates a protective oxide layer on the aluminum surface, improving corrosion resistance and hardness.

- Painting: A traditional method that provides a wide range of color options but may require regular maintenance.

Design Considerations

When selecting aluminum pergola parts, it is crucial to consider key design factors to ensure structural integrity, load capacity, and wind resistance. These factors influence the overall stability, functionality, and longevity of the pergola.

Structural Integrity

The structural integrity of a pergola is paramount for its safety and durability. The parts must be designed to withstand the weight of the pergola’s roof, any attached accessories, and potential environmental loads such as snow and wind. Proper engineering and material selection are essential to ensure that the parts can handle these loads without compromising the structure’s stability.

Load Capacity

The load capacity of a pergola refers to the maximum weight it can support. This is determined by the strength of the parts and their arrangement. When choosing parts, consider the intended use of the pergola and the weight of any items that will be suspended from it. For example, if you plan to hang heavy lighting fixtures or climbing plants, you will need parts with a higher load capacity.

Wind Resistance

Wind resistance is crucial for pergolas located in areas prone to high winds. The parts must be designed to withstand wind forces without buckling or collapsing. This involves selecting parts with adequate thickness and strength, as well as using proper connectors and supports.

Size and Shape

The size and shape of the parts should complement the overall design of the pergola. Larger parts are typically used for larger pergolas, while smaller parts are suitable for smaller structures. The shape of the parts can also impact the aesthetics of the pergola. For example, curved parts can create a more elegant look, while straight parts offer a more modern aesthetic.

Installation Techniques

Installing aluminum pergola parts requires careful planning and execution to ensure a safe and stable structure. Follow these steps for a successful installation:

Site Preparation

* Choose a level site with adequate drainage to prevent water accumulation.

* Mark the location of the pergola posts and excavate holes twice the width of the posts and at least 24 inches deep.

* Fill the holes with concrete and insert the posts, ensuring they are plumb and level.

Part Assembly

* Assemble the pergola frame by connecting the beams and rafters using bolts or screws.

* Install the roofing panels by sliding them into the designated slots or attaching them with clips.

* Add any additional features such as side panels or lighting.

Pergola Securing

* Secure the pergola to the ground using ground anchors or concrete footings.

* Apply a sealant around the base of the posts to prevent water penetration.

* Inspect the pergola regularly for any signs of wear or damage and make repairs as necessary.

Maintenance and Care

Maintaining aluminum pergola parts is crucial to ensure their longevity and aesthetic appeal. Regular maintenance tasks include cleaning, inspecting, and repairing or replacing damaged parts.

Cleaning should be done periodically using mild detergents and a soft cloth. Avoid harsh chemicals or abrasive cleaners, as they can damage the finish. After cleaning, rinse thoroughly with water and dry with a clean cloth.

Inspection

Regular inspection is essential to identify any signs of wear or damage. Check for loose connections, rust, or corrosion. If any issues are found, they should be addressed promptly to prevent further deterioration.

Repair and Replacement

If any parts become damaged beyond repair, they should be replaced immediately. Replacement parts can be obtained from the manufacturer or a reputable home improvement store. Follow the manufacturer’s instructions carefully when replacing parts to ensure proper fit and functionality.

Outcome Summary: Aluminum Pergola Parts

In conclusion, aluminum pergola parts are an investment in both style and durability, offering a myriad of benefits that enhance the functionality and aesthetic appeal of your outdoor space. Whether you seek a cozy retreat or an elegant extension of your living area, these versatile components provide the perfect solution.

By understanding the types, materials, design considerations, and maintenance requirements of aluminum pergola parts, you can make informed decisions that will ensure a beautiful and long-lasting outdoor oasis.